- Green versionView

- Green versionView

- Green versionView

- Green versionView

- Green versionView

Software features

Integration of deep learning and classic algorithms

Neural network driver: Realize complex pattern recognition based on deep neural networks. For example, the VisionPro ViDi module can handle scenes that are difficult to solve with traditional vision technology, such as subtle differences in the surface of parts and natural changes in product color.

Hybrid detection mechanism: Combining traditional machine vision algorithms (such as edge detection, morphological operations) and deep learning models to form a "rules + intelligence" dual verification system, significantly improving detection accuracy and robustness.

Hardware compatibility and scalability

Supports all types of cameras: compatible with analog, digital, color, monochrome, area scan, line scan, high-resolution and other image acquisition devices, and adapts to mainstream interface standards such as GigE Vision and Camera Link in industrial scenarios.

Multi-protocol communication capability: Integrated universal communication interface, which can be seamlessly connected with PLC, robot controller, motion platform and other equipment, and supports industrial field-level data interaction.

Software function

Vision Inspection Tool Chain

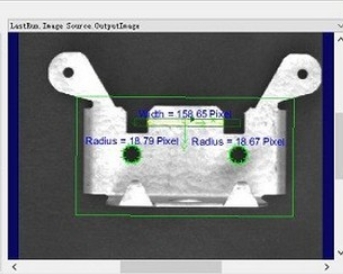

Positioning and measurement: Sub-pixel level geometric feature positioning is achieved through CogFindCircleTool, CogFindLineTool and other tools, and the error can be controlled within ±0.01mm, meeting precision assembly requirements.

Defect identification: The red analysis tool based on deep learning can identify microscopic defects such as 0.1mm scratches and cracks, with a false detection rate of less than 0.1%.

Character recognition: Integrated OCR and OCV modules, supporting the recognition of printed, handwritten, and special symbols, with a character recognition accuracy of 99.99%.

Deep learning enhancements

Small sample learning capability: Only 50-100 annotated images are needed to complete model training, reducing data annotation costs by 80% compared with traditional methods.

Dynamic model update: supports online learning mechanism, which can adapt to changes in product appearance (such as color differences between batches) in real time and reduce the model iteration cycle.

Multi-task collaboration: A single model can handle tasks such as positioning, classification, and defect detection at the same time, reducing resource usage by 30%.

Development environment and deployment

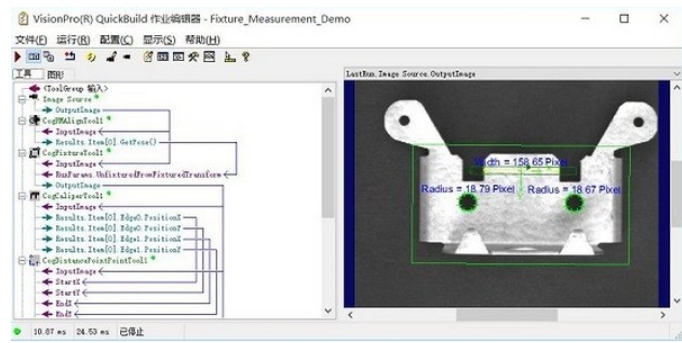

Graphical programming: VisionPro QuickBuild provides a drag-and-drop tool configuration interface, improving development efficiency by 50%.

Cross-platform deployment: supports Windows, Linux, VxWorks and other operating systems, and adapts to various hardware forms such as industrial PCs, embedded controllers, and smart cameras.

Simulation and verification: Built-in virtual debugging function can complete 90% of algorithm verification without physical objects, shortening the project implementation cycle.

Function usage issues

BeadInspect tool usage process: You need to follow the official documentation for detailed operations to ensure that the tool parameters are configured correctly.

Differences in different spaces: VisionPro includes input image space ("."), pixel space ("#") and root space ("@"). You need to select the appropriate space for calibration, positioning or display according to your needs.

Angle variable unit conversion: VisionPro script output is all in radians. If you need angle system, you need to use the CogMisc.DegToRad() function for conversion.

Cognex update log:

1. The pace of optimization never stops!

2. More little surprises are waiting for you to discover~

Huajun editor recommends:

This software of Cognex is completely fool-proof and super simple to operate. In addition, the editor also recommends it.Photo BlowUp,Adobe Illustrator CC,AutoCad 2020,ps download Chinese version free cs6,Picture Factory Official VersionDownload and use related software.

Your comment needs to be reviewed before it can be displayed