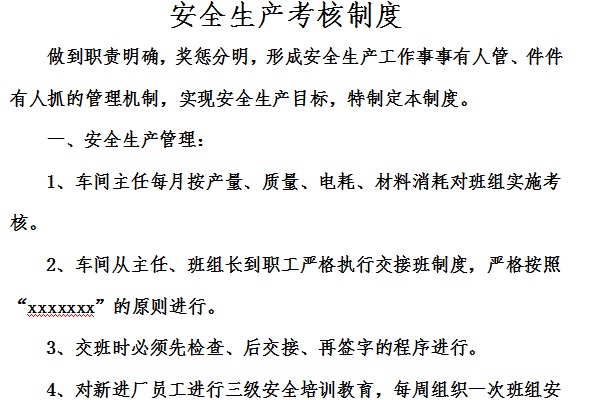

Main contents of enterprise safety production assessment system

Assessment method:

1. Strictly abide by relevant laws, regulations and factory rules, and participate in workshop safety training and education on time.

2. Responsible for the repair and maintenance of raw material workshop equipment, and keeping records; ensuring the normal production of the raw material workshop, and the equipment operation rate reaching xx% or above.

3. When the equipment fails, the maintenance worker should arrive at the maintenance site with tools within xx minutes.

4. When repairing equipment, a maintenance plan should be formulated in advance.

5. During the maintenance process, strictly implement "5S" on-site management, that is, rectify, organize, sweep, clean, self-discipline, and eliminate waste.

Things to note about enterprise safety production assessment system

——Consider what risks exist and what aspects need to be used to control the risks;

——Consider the relationship between each link, that is, the process;

——Consider the specific requirements for the implementation of each link, that is, the application of 5w1h;

——Consider the requirements of laws and regulations, and transform the provisions of laws and regulations into the content of the system;

——Consider what needs to be traced in the system and set up records.

The editor recommends:

The enterprise safety production assessment system is a free template. You can download the source file for you to edit, modify and replace. Huajun Software Park also providesEnterprise assessment system,Employee Appraisal System TemplateDownload.

Useful

Useful

Useful