The meaning of warehouse management measures

Warehousing is a logistics activity

Warehousing is first of all a logistics activity, or logistics activities are the essential attributes of warehousing. Warehousing is not production or trading, but one of the logistics activities that serves production and trading. It should be connected and coordinated with other logistics activities. This is significantly different from the "warehouse management" of the past.

Basic functions of warehousing

The basic functions of warehousing include the entry and exit of items. Inventory and distribution are also the basic functions of traditional warehousing. The combination of the entry and exit of items and warehouse management together constitute the basic functions of modern warehousing.

The purpose of warehousing

The purpose of warehousing is to meet the needs of the upstream and downstream supply chains. This is different from the past which only satisfied There are significant differences in the depth and breadth of “customer” needs. Whoever entrusts and puts forward the demand is the customer; the customer may be an upstream producer, a downstream retailer, or within the enterprise, but warehousing cannot only meet the needs of direct "customers", but also "indirect" Customers are the customers' needs; warehousing should be integrated into the upstream and downstream of the supply chain, and the role positioning and service functions of warehousing should be established based on the overall needs of the supply chain.

Warehousing conditions

The conditions for warehousing are specific tangible or intangible places and modern technology. I say "specific" because the supply chain of each enterprise is specific, and the warehousing location is also specific; of course, the tangible location refers to the warehouse, cargo yard or storage tank, etc. Under the background of modern economy, warehousing can also be in the virtual space. It also requires the support of many modern technologies. Without modern warehousing facilities and information technology, there would be no modern warehousing.

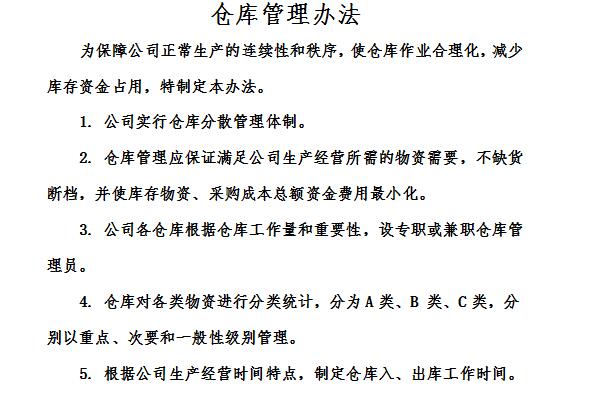

Warehouse management principles

1. Store facing the passage.

In order to make it easy for items to enter and leave the warehouse and move within the warehouse, the basic condition is to store the items facing the aisle.

2. Stack them as high as possible to improve storage efficiency.

To effectively utilize the storage space, storage equipment should be stacked as high as possible. To prevent damage and ensure safety, storage equipment such as scaffolding should be used as much as possible.

3. Select the location based on the frequency of shipment.

Items with a high frequency of shipment and purchase should be placed near the entrance and exit, where they are easy to operate; items with poor mobility should be placed a little further away from the entrance and exit; seasonal items should be placed according to their seasonal characteristics.

4. The same variety should be kept in the same place.

In order to improve work efficiency and storage efficiency, the same items or similar items should be stored in the same place. The familiarity of employees with the location of items in the warehouse directly affects the time of entry and exit. Placing similar items in nearby places can also improve efficiency. important method.

The editor recommends:

The warehouse management method is a free template. The source file can be obtained by downloading, which can be edited, modified and replaced by you. Huajun Software Park also providesMeasures for Supervision and Administration of Food Safety in Catering Services,Measures for the Administration of the Collection and Use of Employment Security Funds for Disabled Personsdownload.

it works

it works

it works