CypCut software functions

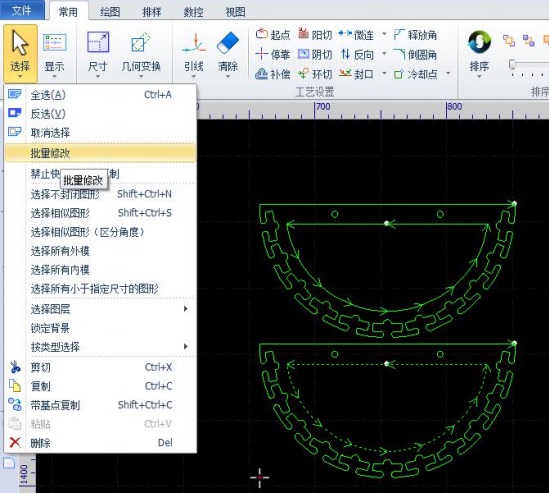

Automatically distinguishes the inner and outer molds, determines the cutting compensation direction according to the inner and outer molds, and conducts lead inspection, etc.

Supports curve segmentation and merging, curve smoothing, converting text to curves, merging and breaking up parts, etc.

The time-saving and labor-saving automatic nesting function can automatically share edges and generate remaining materials.

Supports graphic data formats such as ai, dxf, plt, gerber, lxd, etc., and accepts international standard g codes generated by master cam, type3, Wentai and other software.

Open/Import dxf When waiting for external files, optimization is automatically performed, including: removing duplicate lines, merging connected lines, removing extremely small graphics, automatically distinguishing between internal and external molds and sorting, etc. Each of the above functions can be customized or executed manually.

Supports common editing and typesetting functions, including scaling, translation, mirroring, rotation, alignment, copying, combination, etc.

Set the lead-in and lead-out lines, slit compensation, micro-connection, bridging, Yin and Yang cutting, sealing, etc. in a WYSIWYG manner.

CypCut software features

Simple and clear process settings

After importing graphics, you can quickly set up lead, micro-connection, compensation and other processes. With the batch modification function, you can quickly complete the setting of the entire board process.

Accurate edge-finding assistance

Supports photoelectric edge seeking and capacitive edge seeking to quickly correct plate deviation angles

Import graphics and automatically optimize

When importing external files, the original image will be automatically optimized

Flexible processing control bar

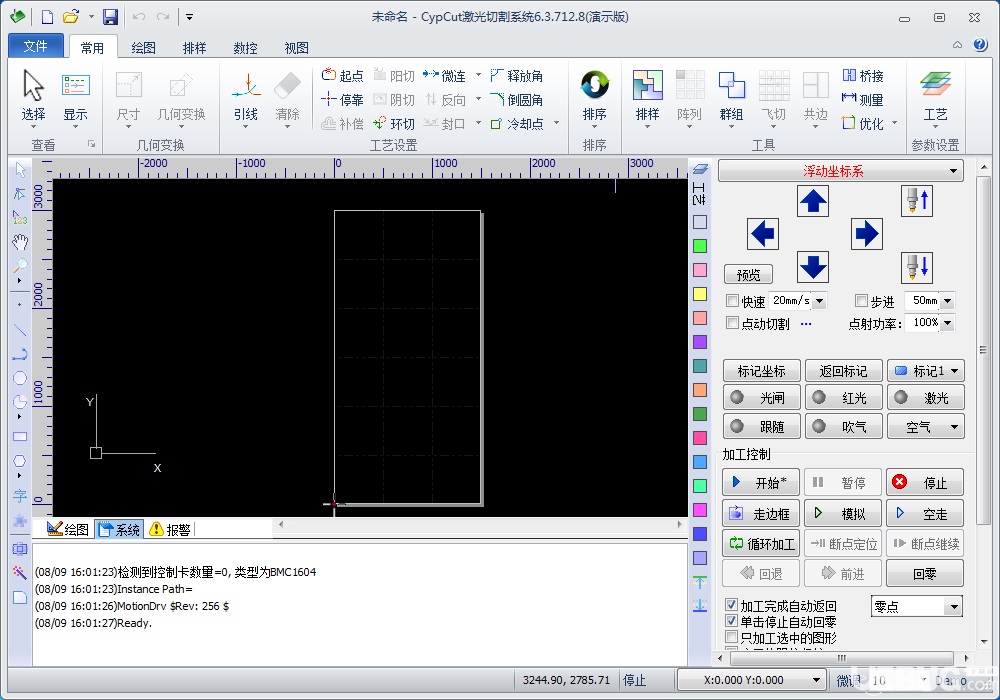

Supports floating coordinate system and workpiece coordinate system, which can not only meet the requirements of flexible production, but also facilitate mass production.

Rich local statistics

It can provide rich and timely statistics on the usage of machine tools.

Dual drive deviation self-correction

Using the gantry synchronization function, the deviation of the dual drive axes will be corrected every time the machine returns to the origin.

CypCut Software Highlights

1. Import graphics, layout, micro-connection

2. Editing and drawing, programmable expansion

3. Graphics optimization, adding leads, and seam compensation

4. Common edge bridging, scanning and cutting, path planning

5. Process design, processing control, automatic edge finding

FAQ

Software runs abnormally

Solution: Before running CypCut, please check whether the dongle is plugged into the USB port and is running normally. If the dongle detection fails, the software will enter the demonstration mode, and all other functions except processing control can be used normally.

CypCut update log

1. Sweep the bug out and carry it out to the end

2. The most stable version ever

Huajun editor recommends:

This software is powerful and easy to operate. I hope you will like it. In addition, this site also hasCruzr,FastCAM automatic programming nesting software,Hanwen production planning and scheduling software,Material weight calculation,Green apple weighing softwareWaiting for software, welcome to Huajun Software Park to download!

Your comment needs to be reviewed before it can be displayed