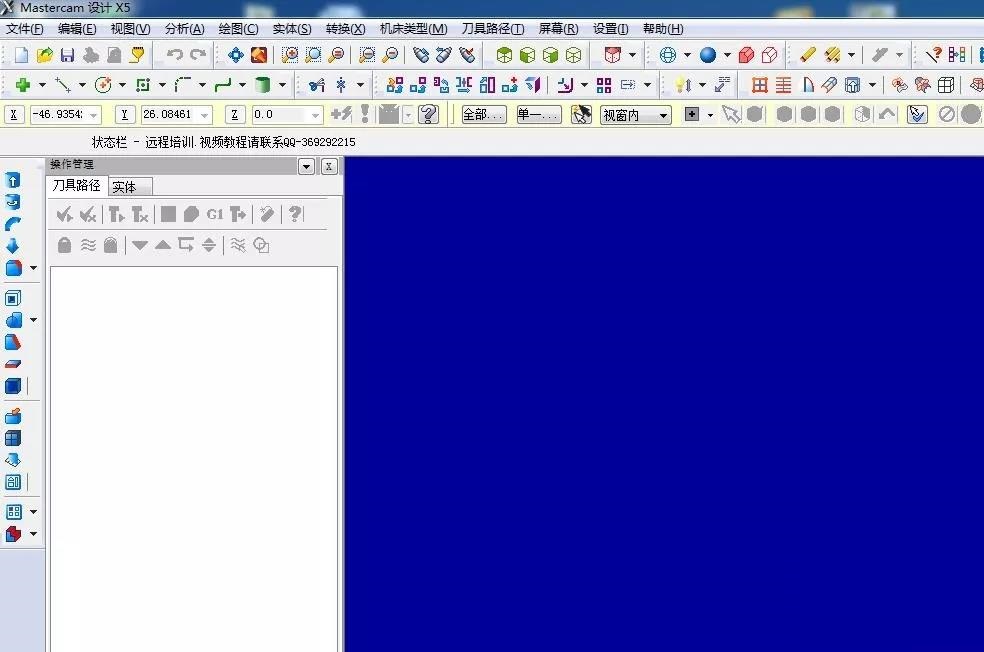

Mastercam X5 software introduction

The Chinese version of Mastercam X5 has convenient and intuitive geometric modeling. Mastercam provides an ideal environment for designing part shapes. Its powerful and stable modeling functions can design complex curved and curved surface parts. Mastercam version 9.0 and above also supports the Chinese environment and is moderately priced. It is an ideal choice for the majority of small and medium-sized enterprises. It is a cost-effective and comprehensive software system and is a CAD/CAM system widely used in industry and schools.

Mastercam X5 Features

1. Precision milling - powerful part model manufacturing

Mastercam's streamlined CAD engine makes design work easier than ever, allowing you to create geometry "on the fly," letting you quickly make changes until it's exactly how you want.

Some of Mastercam’s modeling tools include:

1. Easy to create with complete 2D and 3D geometries including line architecture and surface modeling.

2. Delete trimming boundaries and fill trimming holes.

3. Automatic mold parting and mold manufacturing line calculation.

4. Chuck tool to help position the relationship between parts and fixtures.

5. Associative size updates change your model.

6. Advanced analysis tools to aid modeling and programming.

7. Entity modeling is available as an optional add-on.

8. Built-in IGES format converter, Parasolid, SAT (ACIS entity), AutoCAD (DXF, DWGInventor™ files), Solidworks (including historical tree records), SolidEdge, STEP, Eps, CADL, STL, and more. Siemens' direct conversion NX, CATIA, and Pro/E are also available.

9. Add plug-ins directly to Mastercam and place the Mastercam start button in your SolidWorks, SolidEdge, or AutoCAD Inventor toolbar.

2. CAD file change identification

Mastercam's profile tracking and change recognition give you an easy way to identify CAD edits and modify your toolpaths. Create a CAD file with Mastercam's checklist to alert you when a new version is available and to simultaneously identify toolpath updates in changed areas.

3. Processing material models

A precision machining material model provides a variety of benefits for observation and verification work, because material model comparisons can be made to easily select existing material for machining. Mastercam allows you to create accurate, comprehensive connections and put material models into the process at any time. You can reference the model in the project or save it as a geometry for other purposes. You can even quickly import external CAD models and use material models, further improving flexibility.

4. Intelligent machining

As the world's most widely used CAM software, MASTERCAM integrates your entire work process, from start to finish. Here are just a few of the tools Mastercam offers to help you with most of your work.

5. Capture your processing knowledge

Mastercam provides powerful and complete correlation to capture your work and the foundation of your experience. No matter how complex your program is, you can modify any element of your work and get updated toolpaths immediately without starting over. You can also create a library of favorite processing strategies. And selecting any actions you save as part of their application will help Mastercam adapt to their new model. It's fast, easy, production, modular programming.

6. Confidence index in using machine tools

Reliable Toolpath Verification Understanding your results before starting tool material removal is critical. Mastercam offers you several ways to ensure that your workpieces and scrap come off your machine exactly where you want them. Mastercam's simulator integrates solid cutting verification and toolpath simulation into a powerful set of analysis tools and information in a streamlined interface. Mastercam's simulator allows you to continue working and adjusting projects and displaying tool movements in the same window.

Mastercam simulation provides a variety of toolpath verification options and information

7. Processing machine tool simulation

Mastercam's machine tool simulation displays the entire machine tool and workpiece motion, making it easy to inspect and verify tool paths, axis motion, tool retraction, table movement, and any other elements that affect how the workpiece will interact with the machine. This important information will give you the confidence that what you see is what you will get. Full machine simulation provides a realistic view of your tool paths to interact with your equipment

8. 2D Tool Path

Profile cutting, drilling, and grooving 2D machining range from very simple to very complex. Mastercam provides all the tools needed for these operations. Key points include:

1. Feature-based machining (FBM) automatically writes programs for grooving, contouring, and drilling of solid models, including new spiral cutting and hole correspondence.

2. Standard trenching forms include zigzag, one-way, true spiral spiral with constant overlap, "deformed" trenching, and open trenching.

3. A suite of feed methods, including vertical, spiral, descending, set, intermediate, or custom, including cycloid items.

4. Contour and grooving residual material processing, using smaller tools to automatically clean out material left over from previous operations.

5. Professional support for ISCAR® High Efficiency Machining (HEM) tool library.

6. Area chaining provides a quick and easy way to adjust your 2D high-speed processing area.

7. The ability to click and drag the machining starting point anywhere on your model.

8. Automatic keyway type, circular and thread milling.

9. Contact surface milling can be controlled to eliminate materials using consistent tool loading.

10. Automatic recognition of multiple operations and pre-drilling of own processing points.

11. Automatic drilling and countersunk hole depth calculation.

9. Tool path focus: dynamic milling

Machining time and tool wear are constant concerns for businesses, and Mastercam's dynamic milling is a powerful technology designed to improve this accuracy. Dynamic Milling builds a tool path that continuously adapts to never-go-cut cutting conditions, providing smoother, safer motion. This action is easier on your machine and effectively utilizes the full edge length, greatly extending tool life and eliminating multiple deep cuts. Optimized cutting sequences, specialized motion-holding tooling and other elements combine to deliver parts faster than ever before.

10. 3D tool path

Roughing, finishing, and roughing and finishing of residual materials are necessary to quickly provide a concise and precise efficient NC programming. The following are only some of Mastercam's mainstream 3D machining technologies:

1. Cut polysurfaces, solid models and mesh entities (STL data).

2. It provides unparalleled controlled surface cutting for the refinement of 3D tool paths, and also provides excellent finishing and optimized processing time.

3. High-speed optimization using Mastercam uses a new material model to identify and efficiently machine areas that require a smaller tool for roughing.

4. 3D "projection" machining creates a consistent, smooth finish that follows the natural curves of the geometry. In addition, 3DHST also provides tool path projection based on curves, points, or NCI data.

5. Constant fan machining maintains a consistent tilt and flat surface finish using a consistent 3D step distance.

6. Intelligent hybrid finishing uses slope changes as the model height changes to establish a single tool path cutting method.

7. Contour Z-axis residual material milling (reprocessing) can identify the processing area and critical depth, which requires a smaller tool to cut.

8. Intersection machining Tools can clean hard-to-reach areas along a surface intersection, allowing you to perform one or more precision machining operations.

9. Automatic roughing critical depth.

10. Support complete surface inspection.

Hybrid Smart Finishing combines two efficient cutting techniques in one toolpath. 3D Toolpath Refinement delivers a significantly superior finishing.

11. Tool path characteristics: optimized roughing

Optimized roughing removes bulk material faster and results in more consistent tool wear.

Mastercam Suite's innovative, fast roughing toolpaths - Optimized Center Cutout, Optimized Area Milling, and Optimized Rest Machining are all designed to remove large amounts of material quickly, using our streamlined dynamic milling motions concept.

Starting with larger material, aggressive cuts are followed quickly by smaller cuts, safely delivering complete roughing components that greatly reduce time by up to 60% or faster. Like our dynamic milling toolpaths, these roughing techniques promote longer tool life.

Mastercam X5 update log

1: Brand new interface, refreshing, simple and efficient

2: Performance is getting better and better

Baidu SkydiskExtraction code: xrup

Huajun editor recommends:

Mastercam X5, the software is a very practical software. After continuous optimization, the functions are very good. It is highly recommended for users who need the download experience. In addition, it is also recommended for everyone to use.Haochen CAD,Huiyi CAD,vray for 3dmax2015,CAD Viewer,Quick CAD viewing softwareWait, come and download it

it works

it works

it works