Basic introduction

Luban cutting software is the first professional software in China that can be used for on-site steel cutting. The software interface is simple, easy to learn and use. The calculations are completely open, and experience and practices are added to make the calculation results more practical. The checklist is equipped with a simple construction diagram, making construction of complex nodes extremely convenient. Supports modifying steel bar parameters and graphics in 3D and linking with reports. The built-in processing and material cutting combination system greatly reduces steel bar processing losses. The report function is extremely powerful and can output construction material orders and processing orders. It has completely changed the work process of steel bar cutting and greatly improved the work efficiency of steel bar cutting staff.

Function introduction

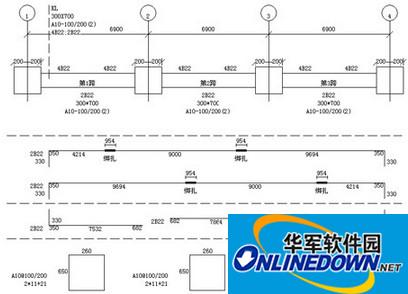

01 Steel skeleton arrangement diagram to guide construction and improve work quality and efficiency

The current way to guide the cutting of steel bars is to write a steel bar list on the template. The original mark may not be found the next day, and the information must be repeated again. Using software, you only need a skeleton arrangement diagram to solve the problem. An arrangement chart can liberate steel bar cutting workers from a large pile of drawings, greatly reducing the labor intensity and error probability of managers.

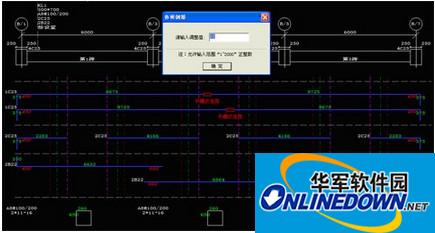

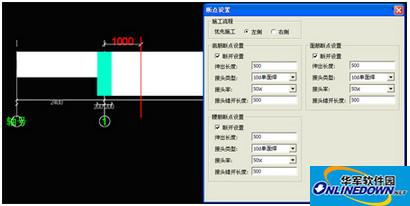

02 Rebar modulus, template adjustment. Starting from the bill of materials, carry out reasonable optimization of steel bar cutting

Rebar modulus setting: The cutting length of the steel bar can be controlled during calculation, and the cutoff calculation is performed according to the module to complete the first step of optimizing cutting; the module setting is flexible, parameters can be customized, and the module can be adjusted by oneself Priority level, the purpose is to minimize steel waste

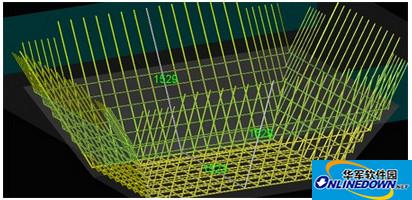

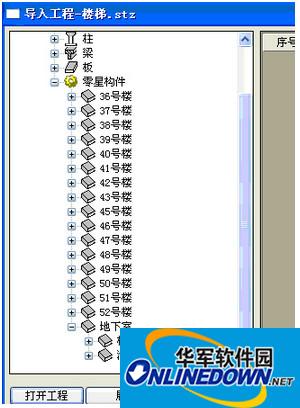

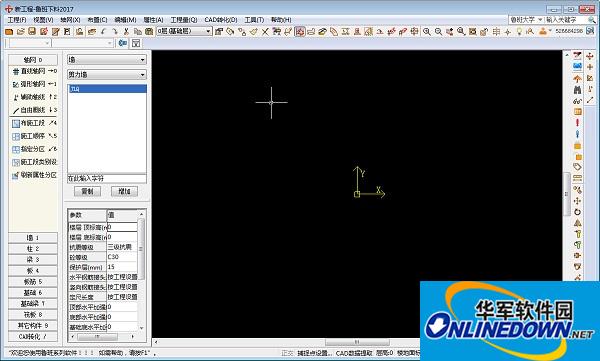

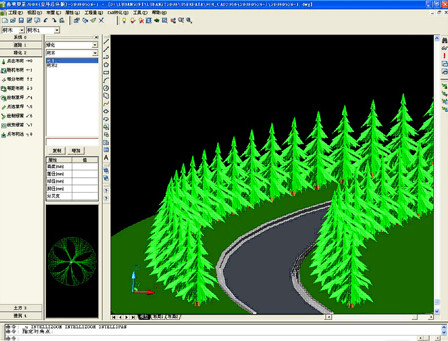

03 3D display and editing of components

It can completely display the architectural model of the entire project, and you can also check whether the component layout is wrong. It also provides a three-dimensional display of the steel bar entities, which can simulate the real on-site steel bar arrangement. For complex components, you can know the construction difficulty and precautions in advance. At the same time, Supports 3D editing of steel bars.

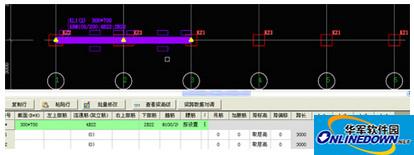

04 Sectional construction of components

The construction site has changed a lot, and one of the biggest headaches for cutting workers is segmented construction. For example, when divided into three sections by traditional manual folding, a beam requires three drawings and three sets of materials. If the position of the post-casting strip in segmented construction is temporarily changed, the material bill will be invalid. The construction joints in the software can be modified at any time, and can be refreshed immediately with just a click of the mouse, and the calculation results will be automatically divided.

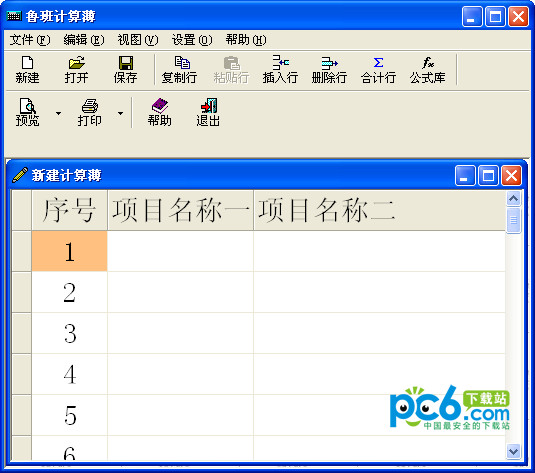

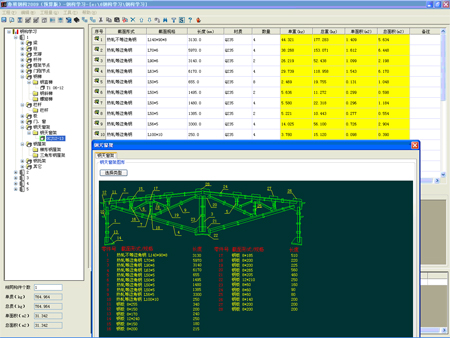

05 Cutting material combination processing table to minimize steel loss

The traditional method of cutting materials is for workers to cut materials one by one or combine them slightly according to the steel bar list. This working process cannot achieve the highest utilization efficiency of raw materials, and the loss rate control is not ideal. The material cutting combination processing table in Luban Steel Bar (Construction Edition) software performs 500 combination operations on the steel bars in the bill of materials to achieve the best combination. The material cutting combination processing table guides on-site material cutting, and the loss can be reduced to lowest, greatly improving corporate efficiency.

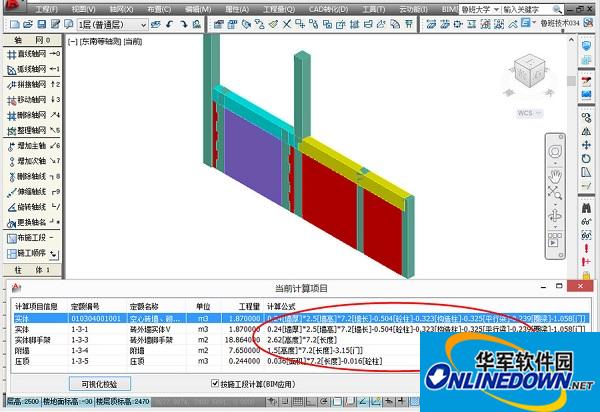

06 Change work processes and reduce work intensity

In traditional steel bar engineering quantity calculations, estimators must first read drawings and establish three-dimensional engineering connections between multiple drawings in their minds, resulting in high work intensity. Using software completely changes the work process. You can get one of the pictures and input the picture information into the computer, without having to worry about the three-dimensional relationship between each picture. The three-dimensional spatial relationships are replaced by computers with geometric information such as axes and elevations, and are automatically processed, which greatly reduces work intensity and complexity.

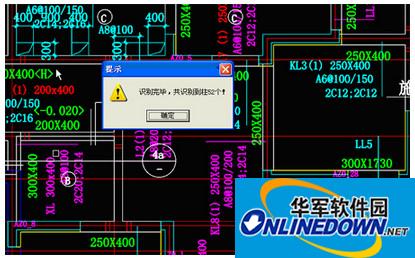

07 Use CAD electronic documents to simplify the modeling process and improve modeling efficiency

The success rate of Luban blanking's CAD conversion is over 95%. It can flexibly respond to various situations on actual drawings, greatly reducing modeling time and significantly improving the work efficiency of steel bar blanking users.

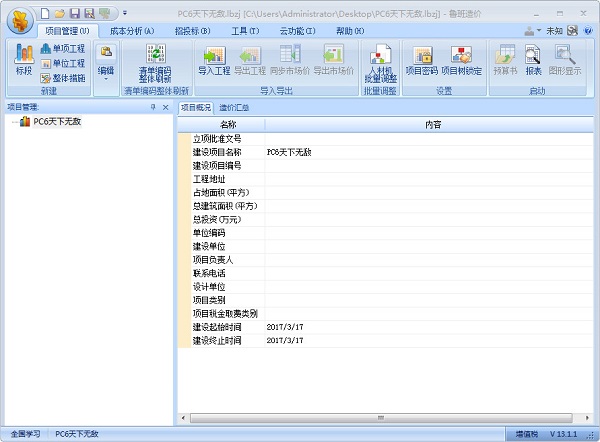

08 LBIM data sharing

The data between various series of Luban software are fully shared, and the construction version and budget version can be opened to each other. The interfaces, operating modes, and data storage methods of the software are the same. Learning one software is equivalent to mastering all software, which improves the user's social competitiveness.

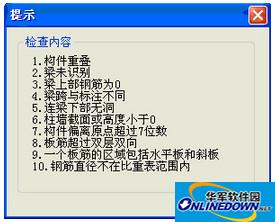

09 Reduce errors and improve the accuracy of engineering quantity calculations

Compared with manual calculation, Luban blanking software reduces data extraction errors and calculation errors. The software automatically applies relevant specification requirements according to the graphics and automatically completes the analysis and calculation. Automatically calculate overlap, hook and bending coefficient (also known as elongation), and obtain the weight of the steel bar based on the diameter of the steel bar. The user does not need to intervene during the entire steel bar calculation process, and the weight and length of the steel bar are automatically calculated. The intelligent inspection system protects users' projects and eliminates worries.

10 Reuse of engineering quantity calculation results

The model established once by the software can be repeatedly used to calculate steel bar quantities for other similar projects.

Software preview

Luban blanking software is usually used in conjunction with Luban steel bars!

Change log

Luban blanking 2017V13.0.0 version

New

1 Project settings

1.1 Added 16G atlas option to project settings

1.2 Anchor overlap value modification, complete entry of 16G anchor overlap value

1.3 Project settings version compatible

2 frame support beams

2.1 Newly added frame support beam strengthening method calculation settings

2.2 Added automatic query logic for frame supports and beams

2.3 Calculation of reinforcement stirrups at the upper wall opening of the frame support beam

2.4 Calculation of reinforced stirrups for column beams

3 frame beams

3.1 Newly added calculation settings for U-shaped reinforcement of cantilever beams

3.2 Support U-shaped bar input calculation

3.3 Adjust the length of the second row of extended supports at the upper part of the cantilever end, and add drop-down options

4 round wall holes

4.1 Added new circular hole reinforcement attribute input

4.2 Support calculation of circular hole stiffeners

4.3 Deduction calculation for vertical bars of shear walls when encountering circular holes

4.4 Deduction calculation for horizontal bars of shear walls when encountering circular holes

4.5 Deduction calculation for shear wall ties when encountering circular holes

5 Add new plate reinforcement to the top of the shear wall

5.1 Added end wall identification and end wall setting functions

5.2 Add new slab negative reinforcement, slab support reinforcement, and calculation settings when the end support of the span slab negative reinforcement is a wall

5.3 Overlap connection between the negative reinforcement of the support plate and the longitudinal steel bars on the outside of the shear wall

5.4 Overlap connection between the support plate bearing steel bars and the longitudinal steel bars on the outside of the shear wall

5.5 The negative reinforcement of the support plate across the plate is overlapped with the longitudinal steel bar on the outside of the shear wall. The outside steel bar can be bent 15*D at the top

6 Added wall insert structure

6.1 Combine the two calculation settings of the bending length of the longitudinal steel bars extending into the foundation floor and the vertical length of the foundation reinforcing bars inserted into the foundation.

6.2 Add new shear wall reinforcements at the next node

6.3 Calculation of anchorage at intervals for main reinforcement support of shear wall

6.4 Compatibility processing of calculation results of old versions

optimization

1 Modification of the default reinforcement level of each component

2 Under 16G, the frame pillars are modified to conversion pillars by default

3 Calculation and setting of beam and column node adjustment, the default data is the same as 16G

4. Adjust the height from the board when tying and overlapping concealed columns.

it works

it works

it works