- Green versionCheck

- Green versionCheck

- Green versionCheck

- Green versionCheck

Haodian Door and Window Design For Excel is a set of auxiliary design software compiled by door and window designers summarizing practical work experience and starting from simplifying daily design work. Through continuous improvement and development, it has now become a set of powerful and easy-to-operate doors and windows. design software. This software is suitable for designers' habits and conforms to the actual design workflow. It can quickly complete a series of tasks such as preparation of cutting orders, preparation of processing details, optimization of wire and plate cutting lists, itemized or summary quotations, and calculation of wind pressure resistance. It also greatly simplifies the tedious statistical summary work of designers, greatly reduces the error rate, and allows designers to devote more energy to the optimization and design of solutions. Most of the report formats of this software are based on Excel, which facilitates data exchange between various departments within the enterprise. The powerful template library function can be expanded by users themselves, providing an excellent implementation platform for enterprise standardization work.

It has been nearly ten years since this software was first used in design work. During this period, it has been actually used by many large enterprises with an annual production volume of doors and windows of more than 250,000 square meters, and has achieved good results. So you can use it with confidence and I believe it will bring you good benefits.

2. Version introduction

The latest version is V10.0. Previously, V1.0, V2.0, V3.01, V3.02, V3.1, V5.0, V6.0, V7.0, V8.0, and V9 were released. .0 and several other versions. The current version is divided into two modules: statistical module (For Excel) and design module (WindowsDesign). In the For Excel section, two new process sheet formats have been added, optimization can limit the cutting short material type on the material, and new functions such as automatic update of grid charts have been added. The WindowsDesign module adds functions such as main material output sorting and formula output. For more new features, please refer to the software user manual.

The software is encrypted using a software dog and has nothing to do with the computer or hardware. There is no need to worry about changes in registration information due to replacement of computers or hardware. At the same time, this version supports stand-alone version and multi-user version. For the multi-user version, you only need to insert the software lock on any computer in the LAN, and other computers in the LAN can use it normally (the number of users that can be used simultaneously is negotiated by the supplier and the buyer during registration. set up). You can choose the corresponding version based on actual usage.

3. Function description of statistical module

1. Material statistics: subdivided into main material statistics, accessory statistics, and glass statistics. Can complete the summary of main materials, accessories and glass in the blanking list within the specified range;

2. Detailed statistics of window number: subdivided into window number main material, window number accessories, window number glass, and window number sample. It can complete the statistical summary of any kind of data in the blanking list within the specified range, and can form a list according to the window number;

3. Door and window table and quantity input: It is subdivided into creating a door and window table and quantity and area input. Various set information can be extracted from the blanking sheets within the specified range to form a door and window summary table. At the same time, the specified number or area of doors and windows can be input into the corresponding blanking sheet according to the window number, thus conveniently realizing Ordering and summarizing materials during batch processing;

4. Wire optimization: During the main material statistics process, the optimization process can be completed according to the set raw material length, incision and other information. You can also complete the optimization process by selecting any two legal values in Excel columns after the statistics are completed and executing the corresponding functions. , the optimized cutting list supports output in Excel for easy editing. At the same time, wire optimization supports reverse sizing of single raw materials and multiple raw materials. Users can design the range, and the software can automatically find the raw materials with the highest utilization rate. The software supports the import function. Users can add data such as remaining materials or raw materials in the historical optimization list as needed. Import the current data for comprehensive optimization. During optimization, the software can set the type of cutting material on a single raw material, thereby reducing the number of tool changes and saving labor;

5. Plate optimization: You can set whether to distinguish the direction of analysis, saw size, etc., which is fully consistent with the one-size-fits-all processing technology, and supports optimization of multiple raw materials, which can well meet the optimization of glass, aluminum plates, stone and other plates in the door, window and curtain wall industry. The optimized cutting list supports exporting to Excel for easy editing and transmission. The software supports the import function, and users can import data such as remaining materials or raw materials in the historical optimization list into the current data for comprehensive optimization as needed;

6. Quotation function: The entire quotation operation is completed in Excel, so the unit price, line weight, cost and other information are output in the form of links to facilitate later adjustments;

7. Template library function: subdivided into template reference, template storage, reference format, template management and other modules. This part can realize the unified management of material orders and facilitate the reference of material orders. For example, templates already exist in the template library to create new materials. The order can be directly extracted from the library, and the size of the lower division is adjusted to complete the preparation process of the cutting order. At the same time, this function provides a good interface for the standardization work of the enterprise and provides a basis for sharing data within the enterprise;

8. Customized format statistics: The format of the material order can be defined according to the habits of different users, and functions such as material statistics, window number material statistics, door and window table statistics, and quantity input can be completed.

9. Extended format statistics: complete material statistics for specific formats;

10. Customized reports: For main materials, accessories, panels and door and window summary tables, users can define report styles that suit their own habits according to actual needs;

11. Network database support (optional function): The line weight library, picture gallery, and material head library can all use the network database function to facilitate the collaborative work of multiple people within the company;

12. Strength calculation function;

13. Thermal calculation function;

14. Other functions: In addition to the above basic functions, the software also has many practical small functions, which users can experience in actual work. For a more detailed introduction, please read the help file or log in to the support forum.

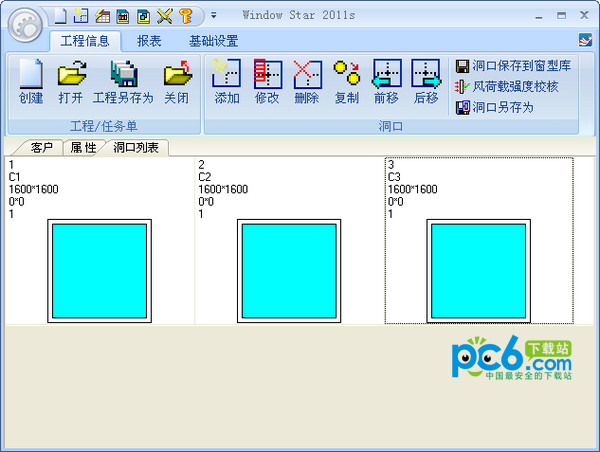

4. Design module function description

1. Interactive drawing modeling environment: The modeling operation is close to the operating habits of AutoCAD, including the use of various shortcut keys, mouse pan and zoom, etc., which helps the operator quickly build door and window component models;

2. WYSIWYG design mode: Various properties of components are displayed in real time. When changing component properties, you can see the results in time;

3. Convenient and fast editing function: you can adjust the size of the graphics by changing the selected grid size, and various operations such as deletion, movement, and mirroring can meet modeling needs;

4. Convenient operation interface: The property window and gallery window can be docked or floating to facilitate user operations;

5. Simple graphic environment: door and window components are simplified into two forms: line components (various profiles) and plate components (glass, hundred-page, etc.). In the system, the divisions of doors and windows can be modeled according to these two components. By designing the display width of the components, a large sample of the same proportion can be generated instantly;

6. Powerful component library function: any component can be saved to the component library, and components in the library can be called for matching during the drawing and modeling process or components can be selected for matching during the editing process;

7. Powerful template library function: any window type partition can be saved to the template library, which can be directly called or combined during the drawing process to speed up the design progress of the window type partition;

8. Completely open database system: Databases of various materials can be maintained by users, and can be imported, exported, printed, etc. in batches;

9. Powerful report function: A variety of reports are available for users to view. They can adjust partial or all material information and cost information as needed, or output quotations according to actual needs;

10. Integrated process design function: Different processing procedures can be set for different components to facilitate process statistics in the production workshop and save statistical time;

11. Conditional formula definition function: The best matching material can be automatically selected based on different lengths of long pieces, area conditions, opening direction conditions, etc.

5. Technical support

Registered users can receive technical support via telephone, QQ online, email, and forum. If other forms of technical support are needed, this can be determined through negotiation between the two parties.

Free version and trial version users can provide QQ online, email, and forum technical support.

Haodian Door and Window Design For Excel V10.0

New feature description:

Haodian Door and Window Design For Excel V10.0 has been greatly improved from the previous version in terms of interface and functions. It has removed some rarely used functions and added more practical functions. The main improvements are as follows:

1. Two new blanking list formats are added. Users can choose the format type to be used according to the actual situation:

1) Standard format that can add or delete rows: Based on the original standard format, rows can be added or deleted to solve the problem that some window types have too many accessories or profiles and require multiple blanking sheets;

2) Vertical standard format: A new vertical blanking order format is designed. The frame, fan profile, frame, fan accessories, opening and fixed glass are placed separately. Statistics can be made separately or summarized according to needs. Set the open fan area to meet the needs of separate statistical fans;

2. The output report adopts a new template, and the table format is adjusted to make the output more beautiful;

3. Brand-new gallery function, the gallery adopts a more intuitive list method, provides more parameter settings when selecting, and improves the efficiency of template selection;

4. The picture library, line weight library and material head library can be expanded into a network database (optional module);

5. Window number material statistics, you can choose a variety of conditions to combine statistics, increasing flexibility;

6. The wire optimization single output report is redesigned and adopts table format. The optimization sheet can choose whether to display chamfer information on the material list or cutting pattern;

7. When using the advanced optimization mode for wire optimization, you can choose to limit the number of tool changes on a single material to improve production efficiency;

8. The reverse sizing of wire adopts a new mode, which can limit the number of raw material types when reverse sizing of multiple materials, and can perform a one-time sizing operation on the statistical table;

9. A new "actuarial mode" is added to wire optimization. If users have higher requirements for optimization rate during the optimization process, they can choose this mode for nesting;

10. When the quantity is reversely entered, the link method can be used, which can be quickly used for statistical operations when placing orders in batches;

11. Added a new material list replacement function, which can replace the material name, code and general information in the material list in batches, improving the reusability of the material list;

12. Added grid chart editing function. You can directly define the grid chart format in Excel and directly link it to the grid size in the blanking list. After modifying the grid size, you can directly read the new parameter value. Generate a new grid diagram and insert it into the blanking list;

13. Added new plug-in management function, which can centrally manage and run various plug-ins we provide or user-customized plug-ins;

14. The quotation adopts a new quotation format, which is more in line with the requirements of the actual tender document;

15. The new version of the software provides more customized interfaces, and we can provide more personalized customization functions according to the actual needs of users;

it works

it works

it works