- Green versionCheck

- Green versionCheck

- Green versionCheck

Aspen software features

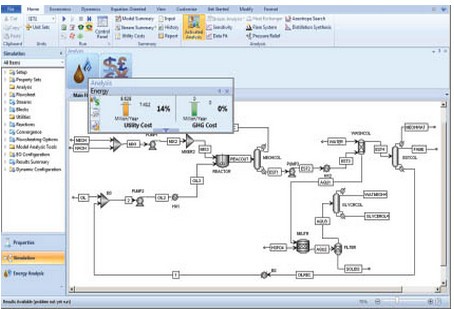

【Energy and Bulk Chemicals】

1. Introducing Unified Production Optimization: Now you can run with 24x7 performance, set more ambitious planning goals and achieve higher throughput using dynamic optimization solutions.

2. Set a more ambitious plan goal: enable the factory to achieve higher throughput than before.

3. Improve plan accuracy: Use refinery simulation models and plant data to seamlessly calibrate and update plans.

4. Improve asset utilization: Improve crude oil selection through prescriptive maintenance notification plans.

5. Reach 24x7 performance limits: Maximize output and profits by dynamically optimizing multiple process units.

【Specialty Chemicals, Polymers and Pharmaceuticals】

Aspen Schedule Explorer – The future of collaboration

Close the gap between sales and operations planning and manufacturing execution by aligning supply chains and operations to promote flawless execution and proactive decision-making.

1. Improve performance against goals: Minimize the gap between plan and actual by understanding production changes and KPIs in real time.

2. Improve product quality: Digitize processes and enhance vertical integration by connecting order entry to production plans.

3. Accelerate time to market: optimize batch and continuous operations while increasing operational flexibility.

4. Drive higher utilization and performance: Support proactive supply chain and operational collaboration and decision-making.

【Engineering Procurement and Construction】

1. Win more projects: Generate bids and estimates faster with lower risk through integrated estimating and risk analysis.

2. Create safer designs faster: Save time by automatically generating and updating device data sheets and safety documents.

3. Diversify revenue streams: Leverage innovations in specialty chemistry models and refinery planning models to drive new business.

Aspen software features

database

Physical property models and data are the key to obtaining accurate and reliable simulation results. It is generally believed that AspenPlus It has the most complete physical property system suitable for industry. In order to standardize their physical property calculation methods, many companies adopt Aspen Plus's physical property system and combine it with their own engineering calculation software.

The Aspen database contains physical property data for nearly 6,000 pure components

1. Pure component database, including parameters of nearly 6000 compounds.

2. Electrolyte aqueous solution database, including about 900 kinds of ion and molecular solute parameters required to estimate the physical properties of electrolytes.

3. Henry constant library, including Henry constant parameters of 61 compounds in aqueous solution.

4. Binary interaction parameter library, including Ridlich-Kwong Soave, Peng Robinson, Lee Kesler Plocker, BWR Lee Starling, and Hayden O’Connell’s equation of state has more than 40,000 binary interaction parameters, involving 5,000 binary mixtures.

5. The PURE10 database includes physical property data of 1,727 purified substances. This is a relatively complete database based on the DIPPR physical property database developed by the American Chemical Society.

6. Inorganic database, including thermochemical parameters of 2450 components (mostly inorganic compounds).

7. Combustion database, including parameters of 59 common components and free radicals in combustion products.

8. Solids database, including 3314 components, mainly used for solids and electrolyte applications.

9. Aqueous solution database, including 900 ions, mainly used for electrolyte applications.

Aspen Plus is the only software approved to interface with the DECHEMA database. This database collects the most complete gas-liquid balance and liquid-liquid balance data in the world, with a total of more than 250,000 sets of data. Users can also link their physical property data with Aspen Plus system connection.

Strong ability

Aspen Plus is a component of the Aspen Engineering Suite (AES). AES is an integrated engineering product suite with dozens of products. Take Aspen Plus Based on the strict mechanism model, AspenTech family software products for different purposes and levels have been formed, and consistent physical support is provided for these software. like:

Polymers Plus:

Based on Aspen Plus, a hierarchical product specially developed for simulating polymer polymerization processes, it has been successfully used in polyolefin, polyester and other processes.

Aspen Dynamics:

After using Aspen Plus to calculate the steady-state process, transfer to this software to calculate the dynamic process.

Petro Frac:

Similar software for refining plants.

Aspen HX-NET:

Aspen Plus can directly provide the pinch technology software with the required parameters such as heat enthalpy, temperature and pressure of each flow section.

B-JAC/HTFS:

Aspen Plus is a software package for heat exchanger detailed design (including mechanical calculations) that can be directly and seamlessly integrated after process simulation process calculations and transferred to equipment design calculations.

Aspen Zyqad:

This is an engineering design workflow integration platform that can be used to integrate and share various work data, reports and knowledge of the entire life cycle from conceptual design, preliminary design, engineering design to equipment procurement and factory operation in a variety of user environments. Aspen Plus has interfaces to automatically integrate with it.

Aspen Online:

The online tool connects the Aspen Plus offline model with DCS or device database management system, automatically checks the model using actual device data, and uses the model's calculation results to guide production.

Two algorithms

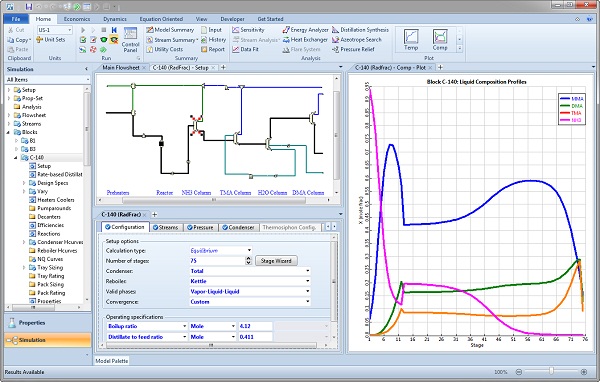

To include the sequential (SM) module and simultaneous equations (EO) algorithms simultaneously in one simulation tool.

The sequential algorithm provides the initial value for the process convergence calculation, and uses the simultaneous equation algorithm, which greatly improves the convergence speed of large-scale process calculations. At the same time, it makes process calculations that were difficult to converge in the past possible. Saves engineers calculation time.

Complete structure

In addition to components, physical properties, and equations of state, it also includes unit operation modules

Aspen module introduction

1. Gas/liquid system

1. Universal mixing, logistics diversion, sub-logistics diversion and component splitting modules

2. Flash evaporation module: two-phase, three-phase and four-phase

3. Universal heater, single heat exchanger, strict shell and tube heat exchanger, multi-stream heat exchanger

4. Liquid-liquid single-stage decanter

5. Yield-based, stoichiometric coefficients and equilibrium reactors

6. Continuous stirred tank, plug flow, batch and discharge batch reactors

7. Single-stage and multi-stage compression and turbine

8. Logistics amplification, copying, selection and delivery modules

9. Pressure release calculation

10. Distillation model

11.Simple distillation

12. Strict multi-stage distillation

13.Multi-tower model

14.Petroleum refining fractionation tower

15. Design and calibration of plate towers, random stacks and structured packed towers

2. Solid system

Venturi scrubber, electrostatic precipitator, fiber filter, screener, cyclone separator, hydrocyclone separator, centrifugal filter, drum filter, solid scrubber, countercurrent decanter, continuous crystallizer, etc.

Aspen update log

1. The pace of optimization never stops!

2. More little surprises are waiting for you to discover~

Extraction code: qr56

Huajun editor recommends:

Aspen software feels really good! The editor specially tested it for this purpose, and it works really well.Leyi integrated ceiling design software,Log volume calculator,Guangdong Provincial Enterprise Income Tax Declaration System,Pyle Glass Optimization Software,Agricultural Bank of China CertificateThese are all very good software tested by the editor, come and choose the one that suits you!

it works

it works

it works