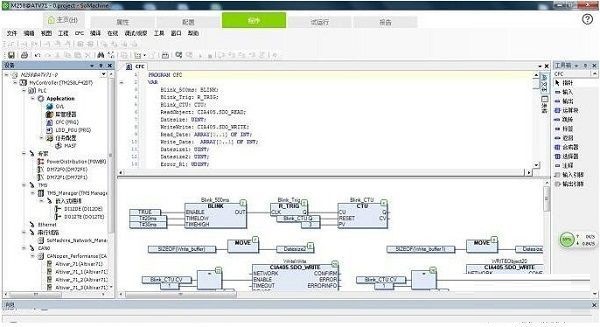

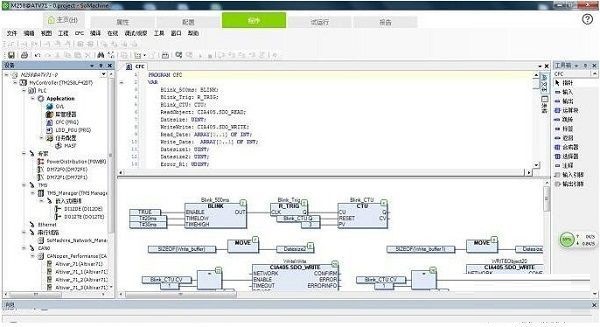

The official version of Schneider PLC programming software is a very excellent plc programming software dedicated to Schneider Electric automation equipment. Schneider PLC programming software supports users to accurately control and manage various equipment through programming. The latest version of Schneider PLC programming software can comprehensively improve the efficiency of product production and is quite practical.

Schneider PLC programmingSoftware features

1. More user-friendly

Schneider PLC programming software official version customizable toolbars and icons

Data input wizard, code syntax analyzer

Integrated diagnostic window

2. Higher standardization level

The case function block includes program segments, data monitoring tables, operation screens, and hyperlinks

Reusable basic functions can be encapsulated in user function blocks (DFB)

The standard function library contains nearly 800 standard functions. You can also add variables, data types or function blocks by yourself

User-defined structured data type (DDT)

3. Higher level of reuse

Function blocks can be reused within applications or between XML import/export projects

Function blocks generate new instances by dragging and dropping them in the library

Schneider PLC programmingSoftware Highlights

1. Schneider PLC programming software has an intuitive user editing and visual programming environment

2. Schneider PLC programming software contains nearly 800 standard functions

3. Practical data input wizard and code syntax analysis

4. Schneider PLC programming software has features such as customizable toolbars and icons and integrated diagnostic windows.

Schneider PLC programming softwareInstructions for use

1. Select "Simulation Mode" in the menu "PLC".

2. Select "Set Address" in the menu "PLC", and select TCP in "Media"

IP, the host IP address must be: 127.0.0.1, and the PLC simulator only supports communication based on TCP/IP.

3. Click "Connect" on the PLC(P) menu

If the connection is successful as shown in the figure below, the icon on the toolbar will be a red ? number on a blue background. If "This is not a valid PLC address, or the PLC is busy, or the medium is closed." appears during the connection operation, it may be due to the following reasons:

1) First select "Simulation Mode" instead of "Standard Mode". (Select in the "PLC" menu)

2) Start the "PLC Simulator" in the program installation directory. (Sometimes it may not be started)

3) If the emulator has a red exclamation mark on a black background, uninstall: Sogou input method, network real name, Internet assistant, Sina Diandiantong, Chinese keywords, 3721 Chinese mail and other software.

4) If that still doesn’t work, run the emulator as an administrator under win7.

4. Click "Transfer Project to PLC(T)" on the PLC(P) menu:

The dialog box that pops up is as follows: Select "PLC to run after transfer" and click the "Transfer" button.

The following dialog box pops up: "Do you want to confirm running on this project (N)?", click OK. It can be seen that the ladder diagram lines and fonts change at this time.

Confirmed:

You can also see that the emulator icon on the toolbar in the lower right corner changes to a blue background with a red play button.

Double-click the emulator icon to pop up the emulator panel. The RUN light is on, the ERR light is off, and the SER COM light is flashing.

5. Then, on the PT side, modify the value, right-click on the timer and select "Modify, enter t#5s;":

6. Assign a value to start, right-click and select start normally open contact→Set value→After setting it to 1, the line turns green. Indicates that the circuit is conducting.

Schneider PLC programmingSoftware support products

1. HMI controller:

- XBTGC, HMISCU, XBTGK, XBTGT2000/4000/5000/6000/7000

2. Magelis HMI&iPC

-XBTGK, XBTGT1005, HMISTO,

HMISTU, XBTGT2000/4000/5000/6000/7000, HMIGXO, HMIGTO, iPC, XBTGH.

3. Motion controller:

-LMC078CECS20T, LMC058

4. Logic controller:

- M218, M221, M238, M241, M251, M258

5. Drive controller:

-ATV-IMC

Schneider PLC programming softwareFAQ

What is PLC programming software?

PLC programming is an electronic system for digital operations, designed for use in industrial environments. It uses programmable memory to store instructions for performing operations such as logical operations, sequence control, timing, counting, and arithmetic operations, and controls various types of machinery or production processes through digital and analog inputs and outputs. Programmable controllers and related equipment should be designed according to the principle of making it easy to form an industrial control system into a whole and easy to expand its functions.

With the rapid development of microprocessors, computers and digital communication technology, computer control has expanded to almost all industrial fields. Modern society requires the manufacturing industry to respond quickly to market demand and produce products in small batches, multiple varieties, multiple specifications, low cost and high quality. In order to meet this requirement, the control system of production equipment and automatic production lines must have extremely high reliability and flexibility. PLC programming appears in response to this requirement. It is a general industrial control device based on microprocessors.

Schneider PLC programming software update log

1.Fix several bugs;

2. Optimize detailed issues;

Huajun editor recommends:

Schneider PLC programming software has always been a common programming tool for most netizens. Its dominant position in the minds of netizens can be seen. It is strongly recommended that users download Schneider PLC programming software and use it. Come to Huajun Software Park to download it. In addition, Tarma QuickInstall, appmaker, and cloud machine manager are available for download.