The latest version of Cimatron CNC programming software is a mold design tool often used by hardware mold manufacturers. The official version of Cimatron CNC programming software supports all current industry standard data information formats, including IGES, VDA, DXF, STL, Step, RD-PTC, CATIA, DWG, etc. Cimatron CNC programming software can also shorten mold design time by 70%, reduce mold costs by 16%, shorten injection molding cycles by 14%, and improve product quality overall.

Cimatron CNC programming software function introduction

Cimatron e14 has more than 200 new features and enhancements for the entire production range on the production floor. From tool design to CNC programming, the latest version helps ensure our customers are more efficient than ever in a competitive market.

1. NC – New cutting strategies allow faster machining times using tools such as barrel, oval, lens tools and more. Overall, roughing time is reduced by an average of 20%. A new guided cleaning process allows control of the milling direction for each area in the cleaning. Improved 5-axis tilt tool path and guide curve controllable tilt.

A large number of new and improved functions improve the programming automation of sheet metal processing, such as the function of automatic drilling as a veneer program, automatic corner recognition, wide pocket recognition and pocket automation using templates.

2. DIE – The new integrated incremental analysis option enables users to accurately simulate designs and discover design defects before manufacturing. Users can see if they have carrier or material issues, suboptimal stamping results or springback, and incorrect pressure definition.

New advanced mold design geometry tools such as addendum faces and fuzzy offsets are added to expand application functionality.

3. Computer-Aided Design of Tools - Implemented many long-requested enhancements in parts, assembly and drawing for faster and simpler design. New enhancements to Cimatron's grid kernel include the introduction of robust selection tools for the split/copy and add/remove commands. Additionally, advanced 3D text functionality is now available for meshes and solids

4. Molds and Electrodes – New features and enhancements for faster and safer mold design, such as hole (cooling) verification of different diameter injectors, hole (library) identification and processing.

5. Integration of PLM and Windchill – Integration with PTC Windchill PLM system. This integration allows Windchill users who use Cimatron files to perform Windchill operations (such as synchronization, checkout/checkin, etc.) from a Cimatron assembly or from the Cimatron browser.

Cimatron CNC programming software software features

1. Brand new user interface, easier to learn and use, Cimatron includes many new features and functions

2. Rich tool and mold CAD functions facilitate rapid design, including direct modeling, new patch operations with hybrid modeling functions, and enhanced assembly functions.

3. Improved the drawing function, dynamically creates multiple views, and can create shadow maps

4. New cavity mold application tools, gate design for more reasonable process design, conformal cooling tools for easy design and curved cooling channels, shortening the injection molding cycle and preventing part deformation

5. Independent operating environments for progressive dies and transfer dies to quickly design various types of stamping dies

6. Intelligent mirror electrode tools and hybrid design environment, automated physical tools accelerate electrode design

7. New template processing solution, providing a complete set of fast, efficient and automatic processing for cavity molds and stamping molds

8. The new inspection program of CNC machine tools defines the inspection cycle in the NC environment and realizes online monitoring, so that the workpiece can be adjusted from time to time on the machining center to improve the machining accuracy!

9. New functions for milling and drilling and improved NC programming functions improve the programming automation of roughing, finishing and 2.5-axis machining. The parallel design and manufacturing environment allows multiple users to assist in completing the same project at the same time.

Cimatron CNC programming software installation steps

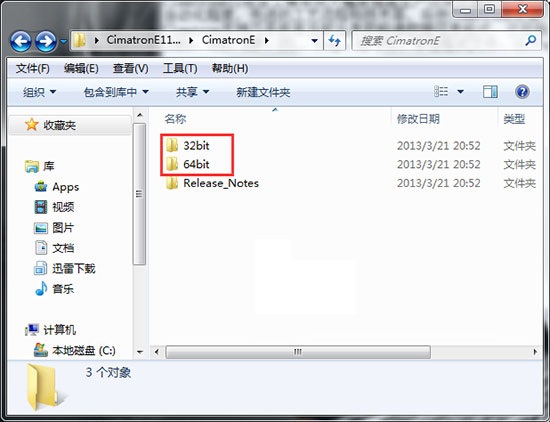

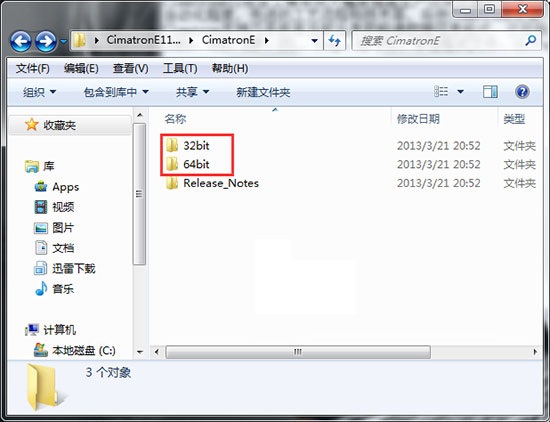

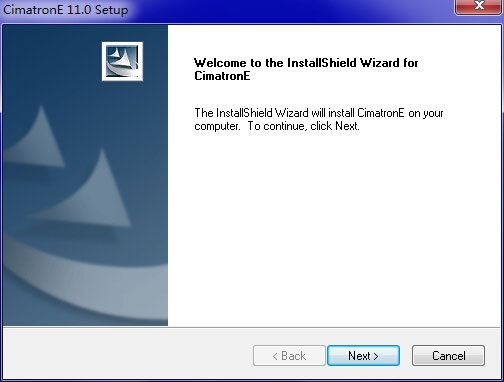

1. Download the Cimatron CNC programming software from Huajun Software Park, then unzip the installation package and open the "CimatronE" directory. There are two folders, 32bit and 64bit. Please open it according to your operating system, and then run the installation program. "setup.exe"

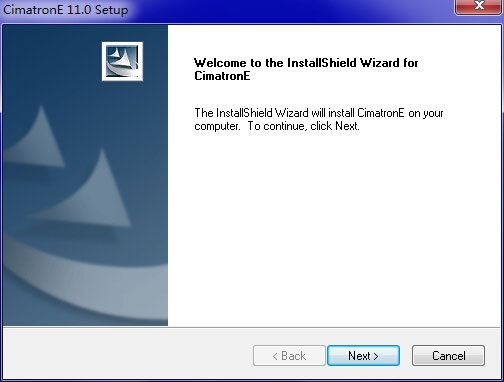

2. In the installation interface, we need to click NEXT

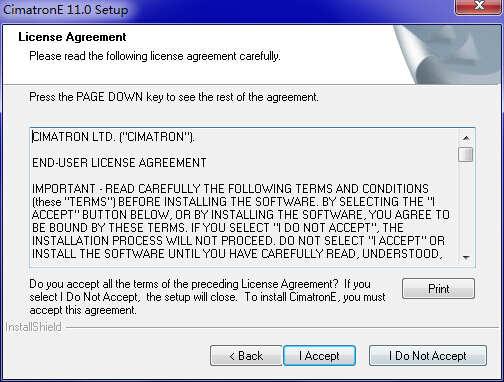

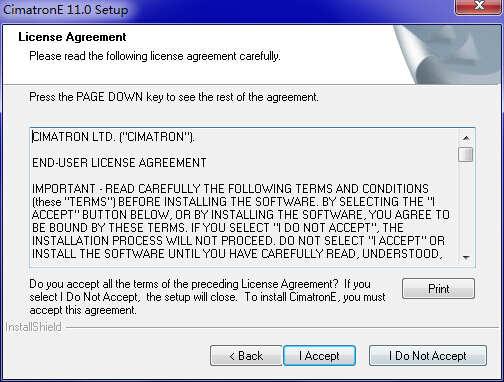

3. At this time we need to click I Accept

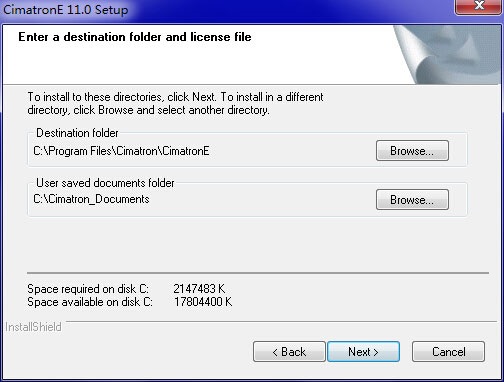

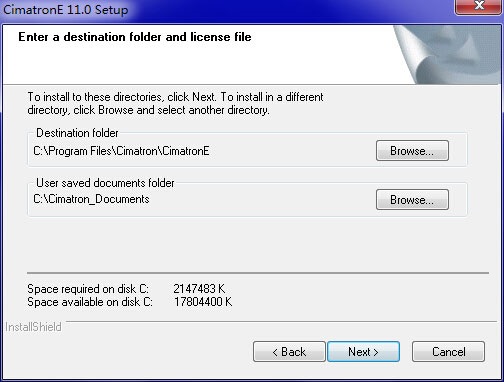

4. Select the software installation directory. The default installation location is C drive. Huajun editor recommends installing it on D drive.

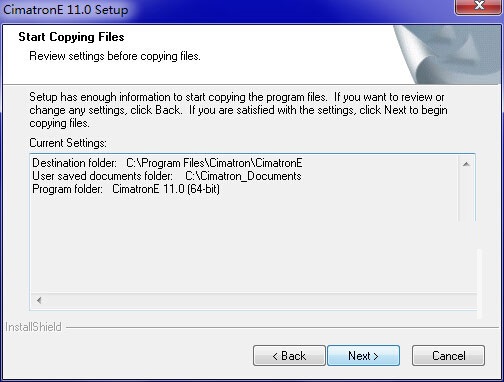

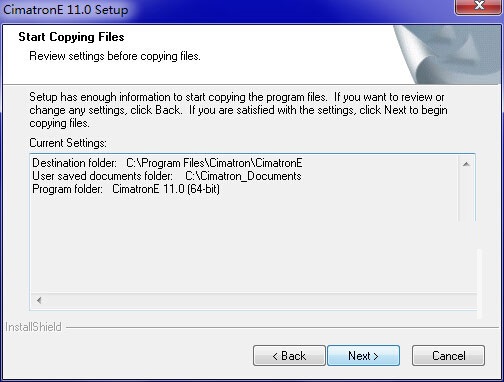

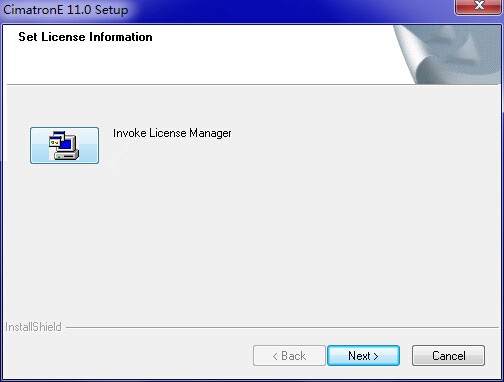

5. After confirming the directory, click NEXT to start the installation.

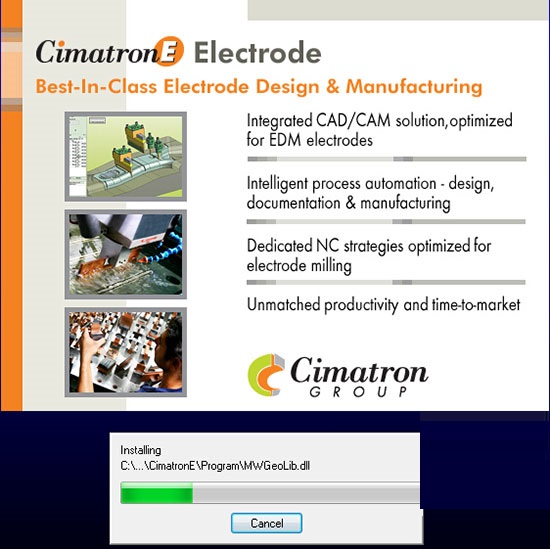

6. Cimatron CNC programming software is being installed, waiting for the progress bar to be full.

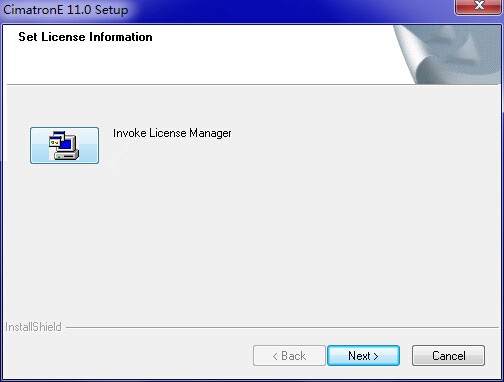

7. Cimatron CNC programming software installation is completed

Cimatron CNC programming software update log

Developer GG said there are really no bugs this time~

Special instructions:

Hello, the software you are about to use is an auxiliary tool and may be intercepted and checked by major anti-virus software. There may be risks in using this software. Please pay attention to avoid it. If you want to continue using it, it is recommended to close various anti-virus software before using it. .

Attached is the software package decompression password: softwaredownload4.com

Huajun editor recommends:

If you are dazzled by the introduction of so many functions above, then quickly download Cimatron CNC programming software. This site also provides .NET, Batch Butler, Cloud Machine Manager, etc. for you to download.