The official version of the robot simulation software is a powerful robot programming tool. The latest version of RoboDK robot simulation software can help users design robot work cells, generate robot programs through offline programming, and control robot actions. Robot simulation software supports functions such as pick and place, spray painting, and robot processing, effectively improving the simulation efficiency of industrial robots.

Introduction to robot simulation software

RoboDK is a powerful and cost-effective simulator for industrial robots and robot programming. This software is a valuable tool for robotics system integrators and robotics programmers.

RoboDK is software for simulation and offline programming. Offline programming means that robot programs can be created, simulated and generated offline for a specific robot arm and robot controller.

RoboDK can help you with manufacturing operations involving industrial robots.

Robot simulation software functions

RoboDK software is powerful and professional. You can use this software to write robot programs on your computer. After simulation and debugging, you can load it into the robot controller and run it. This type of software exists to help users simplify the entire process from design to production. Using the software, you can simulate industrial robots and directly generate readable programs for the robot controller on your PC. Offline programming is possible, which means you can effectively avoid production downtime caused by online programming. Offline programming and simulation can also better plan and debug your work, avoid unnecessary errors, ensure the best results, and shorten project time. In addition, you will not have such restrictions when using software. The application programming interface (API) means that you can use Python to program the robot.

In addition, the software supports multiple brands of robot controllers and can output corresponding program files for your robot at any time. You can also edit the post-processor as needed to achieve the desired functions. The software uses new programming tools that can reduce production time from weeks to one day, thereby automating short-term production. With the help of it, you can easily use any robot for any manufacturing application such as robotic machining, milling, welding, spray painting, 3D printing, calibrating robots, etc.

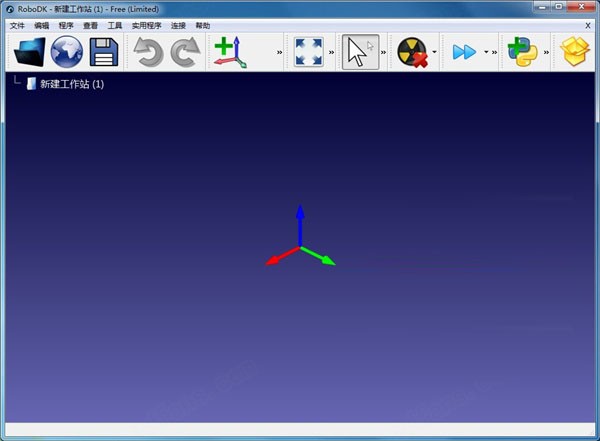

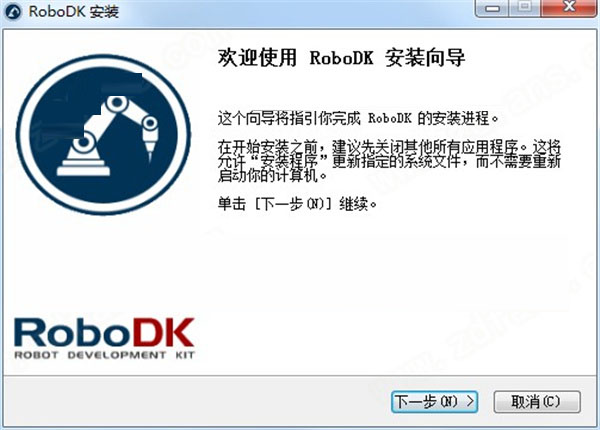

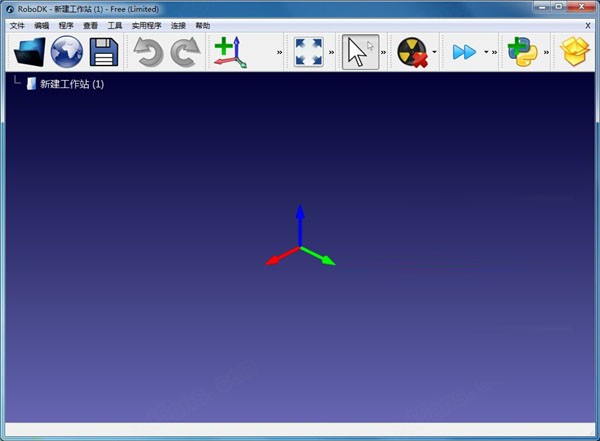

Robot simulation software installation steps

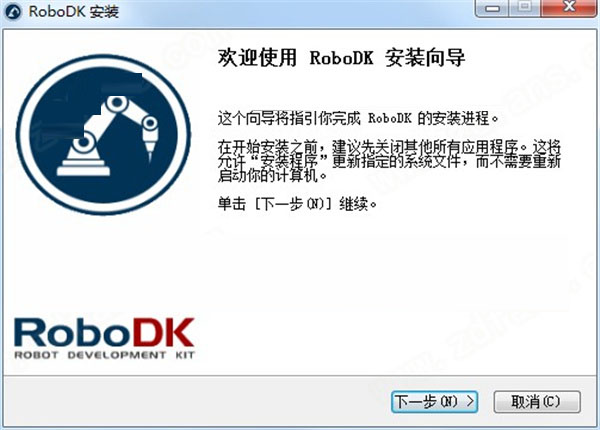

1. Download the official version of the robot simulation software installation package from Huajun Software Park. After unzipping, double-click the exe program to enter the installation wizard and click Next

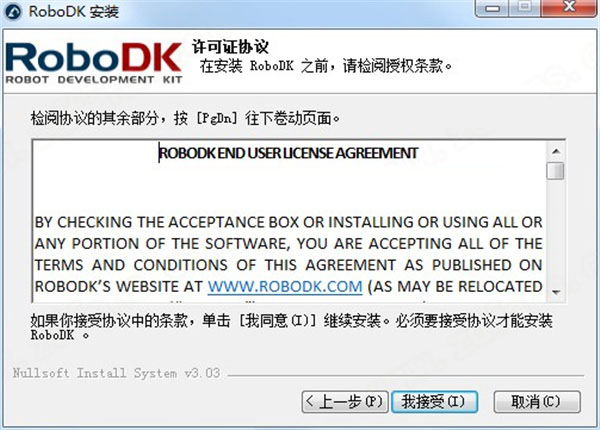

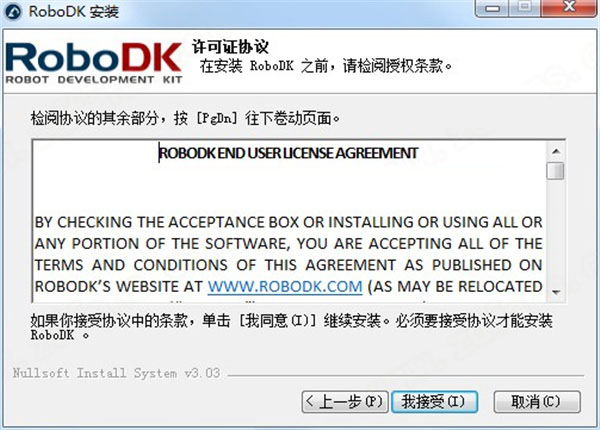

2. Read the license agreement and click I accept

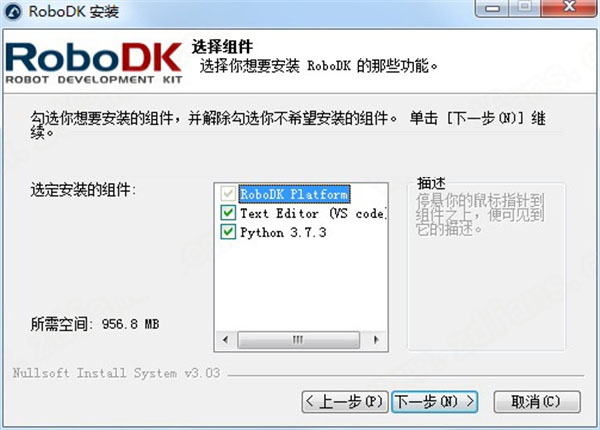

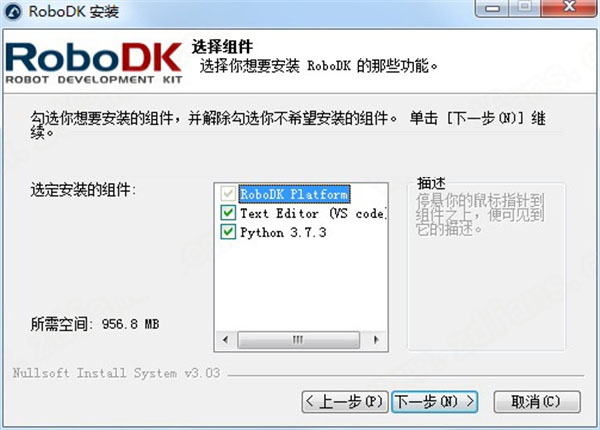

3. Select the components to install and click Next

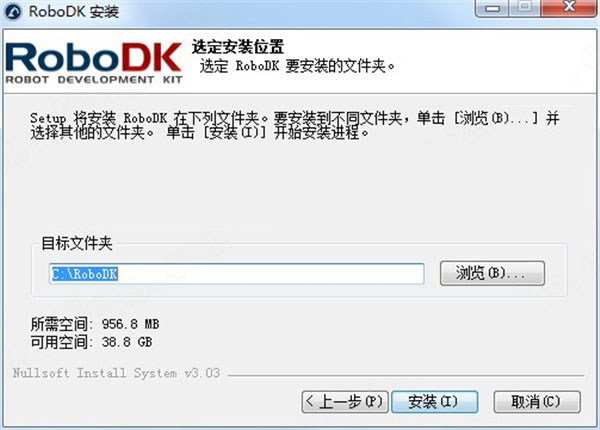

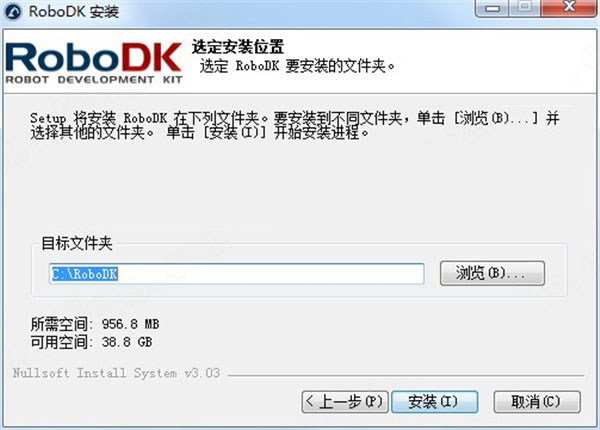

4. Click "Browse" to select the installation folder. Generally, it is installed on the C drive of the computer by default. It is recommended to install on the D drive. Click Install.

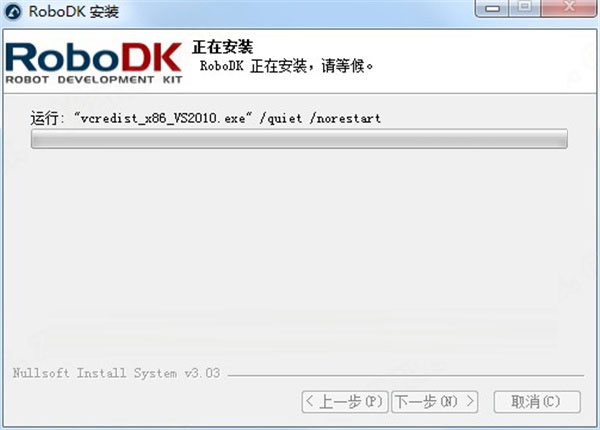

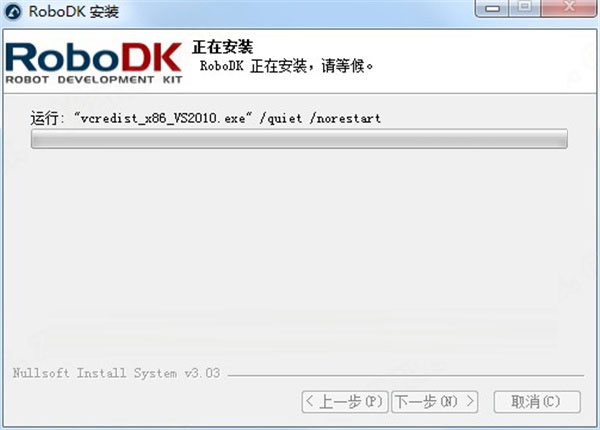

5. The software is being installed, please wait patiently.

6. The installation of the robot simulation software is completed, click Finish to exit the installation wizard

Robot simulation software FAQs

System incompatible

Some robot simulation software may not support all versions of operating systems. For example, some software may not support Windows XP or the latest versions of Windows systems.

Solution: Check the software's system requirements and make sure your computer operating system is compatible with the software. If it's not compatible, you may want to consider upgrading your operating system or installing an older version of the software.

Robot simulation software update log

1: Brand new interface, refreshing, simple and efficient

2: Performance is getting better and better

Huajun editor recommends:

Robot simulation software, word-of-mouth software, guaranteed to solve all your problems! The editor highly recommends! This site also has similar software door and window CC manufacturer version, Jinzhi, and .NET. If you are interested, you can download it!