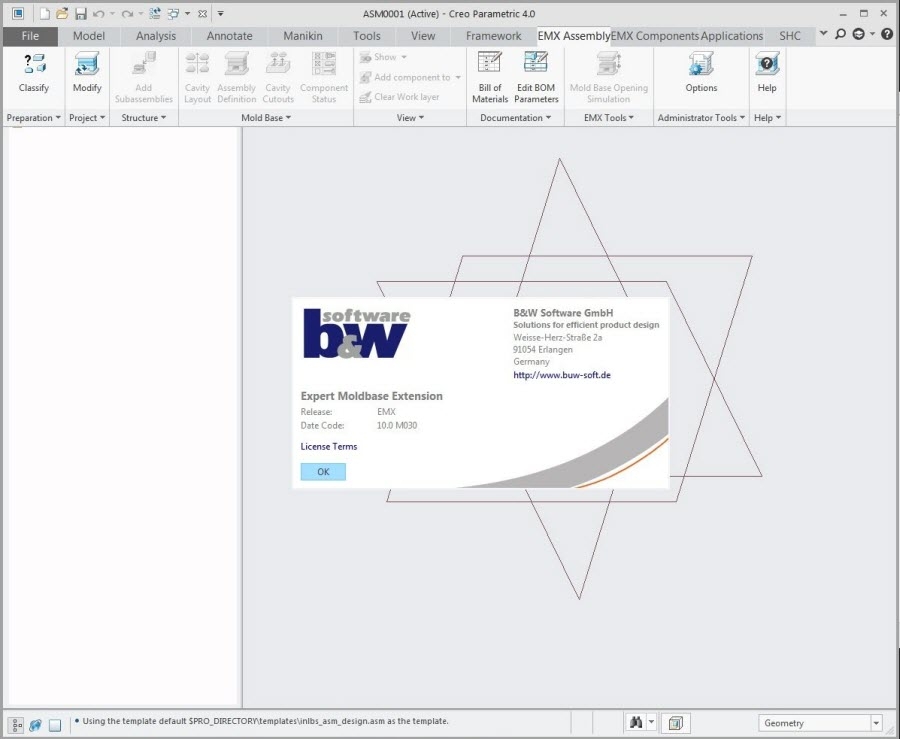

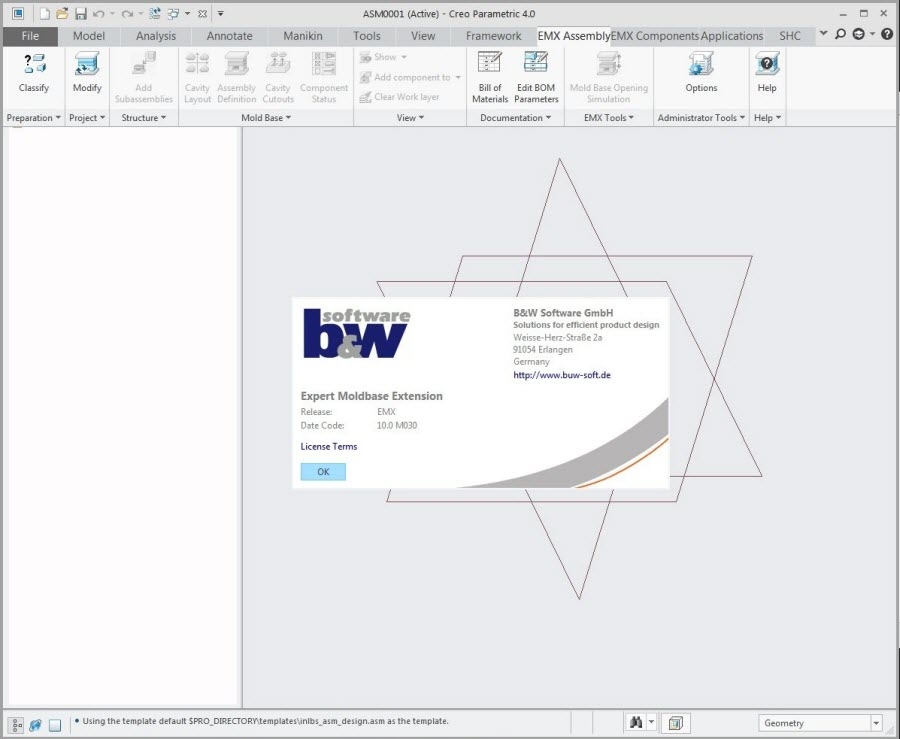

EMX official version is a powerful module design tool. Creo

The latest version of EMX can help designers directly call the company's mold base, save mold design and development time, improve work efficiency, and is suitable for Creo2.0, 3.0 and 4.0 versions. Creo

EMX software supports automatic generation of 3D models, is interoperable, open, and easy to use, greatly simplifying the design cycle.

EMX software introduction

Speed design by automating mold base design and detailing with simple process-driven workflows

Library containing suppliers of 17 mold bases/components (e.g. screws, ejector pins, slides, cooling joints)

Automatic ejector, waterline and joint functions, automatically complete flow channel and waterline inspection

eliminated many errors, thus preventing expensive rework overhead and reduced cycle time

Reduces the need for redesigns by automatically updating mold models, drawings, and electrodes

EMX software features

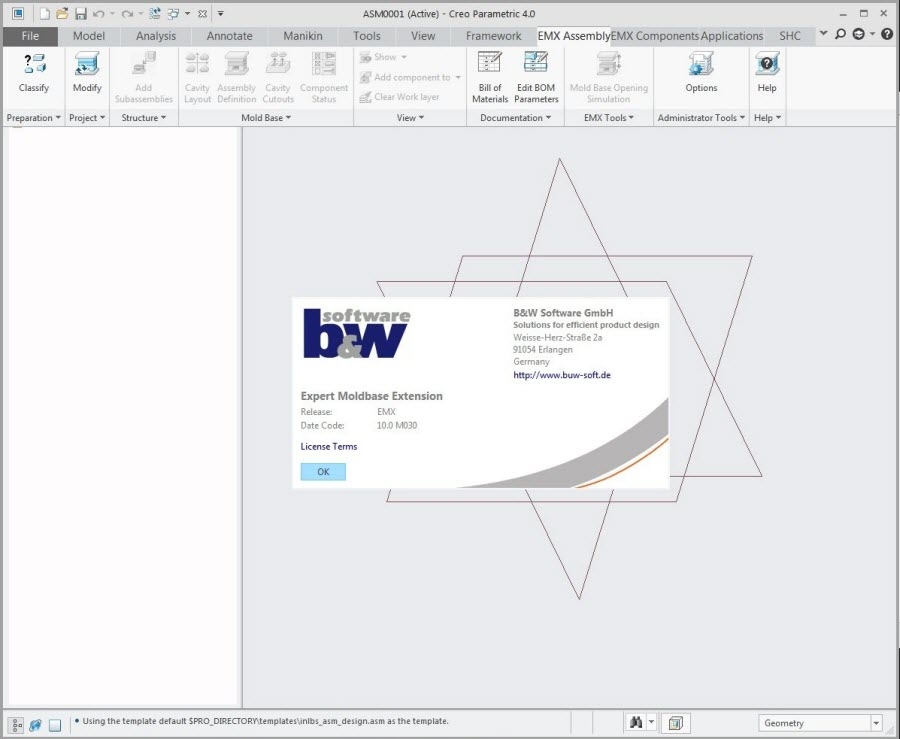

1. PTC Creo EMX is an indispensable add-on tool for moldmakers and moldmakers, eliminating time-consuming, tedious tasks and the need for data conversion that often slow down the product development process.

2. PTC Creo

EMX allows users to create mold base layouts in a familiar 2D environment and automatically generates 3D models to take advantage of 3D design. The 2D process-driven GUI guides you toward optimal designs and automatically updates during mold base development. You can choose from a catalog of standard components (DME, HASCO, FUTABA, PROGRESSIVE, STARK, etc.) or custom components. The resulting 3D model is then used for interference checks during mold opening, as well as for automated generation of deliverables such as production detail drawings and BOMs.

3. PTC Creo

EMX increases design speed because the unique graphical interface gives you a fast, real-time preview before automatically placing a 3D component or assembly. Once components are placed, operations such as gap cuts, drilled and tapped holes are automatically created in corresponding adjacent boards and components, eliminating tedious and repetitive mold detailing tasks. PTC

Creo EMX also enables moldmaking companies to capture their unique design standards and best practices directly in mold components and assemblies.

EMX software features

Feature one

Quickly select and modify the following content

Mold bases and accessories.

Select the ejector pin specifications and automatically cut out the corresponding hole positions and counterbores.

Easily design water holes according to predefined curves and install water pipe plugs.

The system presets BOM and parts drawings.

Feature 2

Complete slider structure, including screws, pins and automatic grooves.

Complete mold opening mechanism, including screws, pins and automatic slotting

Complete sloping roof structure, including screws, pins and automatic slotting

Simulate the mold opening process

The hole table function in the plan view.

Feature three

——Automated configuration

being

Preset parameters and parameter values of various parts

Bolts and pins are installed automatically.

Various types of parts are automatically generated and assigned to the corresponding layers

Various simplified expressions

Preset hole clearances for all bolts, pins and thimbles.

EMX update log

Working day and night just so you can be happier

are all gone!

Huajun editor recommends:

EMX is a very good software that can solve a lot of troubles. This site also provides vect2000 vectorization software, Hanwang attendance management system, cloud machine manager, etc. for you to download.