Code accuracy is the lifeblood of machining. KS wire cutting uses a new error isolation algorithm to effectively ensure zero errors within 2,000 codes.

I don’t know, but I was shocked when I compared it. KS generated 400 codes and the zero calibration result was (0,0). CAXA generated the same 400 codes and the zero calibration result was (11,9).

The importance of zero calibration is not only to verify the correctness of the code, but also to verify the usability of the code. Those codes with too large errors are not usable.

1. Support layers.

2. Supports labeling and can mark dimensions.

3. Supports 1:1 printing and fixed-height printing.

4. Supports background connection, allowing you to draw online without any errors.

5. Supports algebraic input. You can easily use addition, subtraction, multiplication, division, exponentiation and common trigonometric functions when inputting data.

6. Supports point capture, which can capture circle centers, straight line midpoints, circle and arc quadrant points, and intersection points.

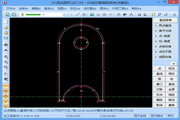

7. Complete data interface function, can directly open data files of CAD (Dxf) and popular wire cutting software Autop, Towedm, YH, PM-A95.

Useful

Useful

Useful