Xinhe Cloud Production Management Software ERP+MES

Xinhe Cloud is a full-stack digital factory solution for discrete manufacturing. Through cloud ERP+MES, Xinhe Cloud focuses on core pain point scenarios such as scheduling, production, quality, orders, procurement, and inventory in the factory, integrating industrial data at the equipment level, and has been used in automotive parts, equipment manufacturing, national defense and aerospace, and high-end electronics. The component industry has accumulated hundreds of customer cases and industry solutions.

Product parameters

Product introduction

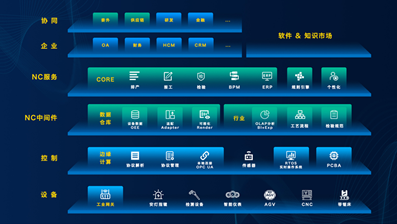

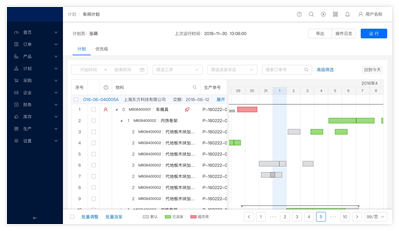

This product provides nine production-related functional modules in workshop-level management, including orders, procurement, inventory, production scheduling, work reporting, inspection, materials, supply chain, and Kanban. Establish direct connections with production equipment through self-developed industrial gateways to obtain more accurate real-time data in production scheduling, work reporting, inspection and signboard modules. In the industry analysis module, the algorithm team will complete industrial big data analysis, create an optimal production model by monitoring multi-dimensional data of production equipment in real time, and provide early warning of production anomalies.

Service scope:

This product focuses on opening up the entire process of enterprise production and operation. In the process of helping customers realize factory digitization, it focuses on the construction of intelligent production and intelligent management.

In terms of intelligent production, it can help the discrete manufacturing industry establish intelligent production standards, which mainly include production control and optimization, intelligent diagnosis and maintenance. It is used to stipulate the requirements that should be met in planning and scheduling, production execution, quality control, equipment operation and maintenance, etc. during the production process. Focus on discrete manufacturingMESWorkshop-level management processes such as application; enterprise-level management processes such as planning management, production management, quality management, equipment management, and logistics management; visual management methods such as product information visualization, equipment information visualization, inventory information visualization, and production status visualization to ensure Standardization and leanness of management processes.

Technical advantages:

supportFPGAedge nodes: independently developedPlug-and-playThe industrial gateway can complete the collection of production equipment operating data in the near field, clean the data, and complete real-time transmission (thanks toRTOS).

NCmiddleware:

The adapters in its own ecosystem complete the conversion of data formats, resulting in lower data signal-to-noise ratio and stronger integrity and reliability. useHadoopTo manage production big data, and train models through machine learning algorithms including random forest algorithms, combined with domain knowledge, to complete the prediction of production anomalies and the optimization of production schedules.

Production microservices:

All functional modules that extend the production process are all microservices, truly achieving multi-tenant configurability and meeting customized needs at a lower cost.

After-sales service

To protect your rights and interests, please do not conduct offline transactions! 90% of frauds, disputes, and fund thefts are caused by offline transactions. Tencent Cloud Market provides you with the following service guarantees:

Quality service merchant

Strict access and providing massive cloud services

7*8 hours online customer service

Full online consultation to help you shop with peace of mind

Professional testing ensures quality

Safety monitoring to ensure product quality

Worry-free after-sale service

If you are not satisfied, you can get a refund and worry-free after-sales guarantee.